Piston Rod Stuffing Boxes

Reliable sealing for main engine performance

Proven design, trusted by engine builders

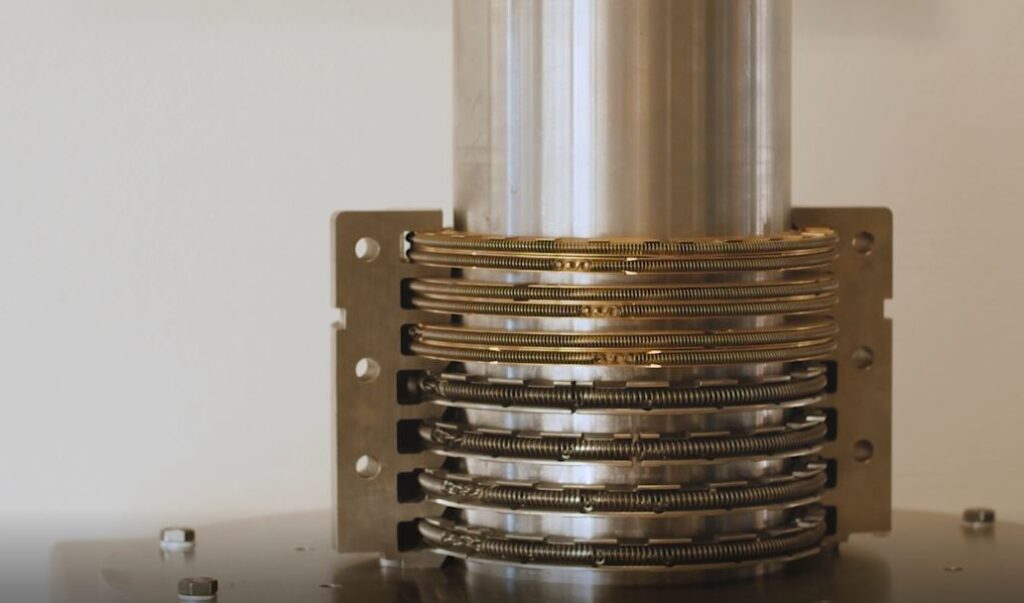

At HECO International, we specialise in the manufacturing of high-precision piston rod stuffing boxes for two-stroke diesel engines. A stuffing box in a main engine may seem like a minor component, but this plays a vital role in securing the separation between the clean crankcase and combustion chamber. This ensures optimal lubrication conditions and prevents contamination – essential for reliable engine operation.

We were the first to introduce the piston rod stuffing box design with replaceable lamella scraper rings – a solution that has set new standards for the industry. Although stuffing box types have evolved over time, the core function remains the same: to protect your engine.

Every HECO stuffing box is designed in close cooperation with leading engine designers and manufactured to exact specifications. This makes our products the preferred choice for both newbuilds and retrofits.

Three essential ring types

Each stuffing box we deliver includes three precision-engineered ring types:

- Top scraper rings – remove combustion residues from the piston rod.

- Sealing rings – ensure a pressure-tight seal between the scavenging air space and the crankcase.

- Lamella scraper rings – reduce oil loss by removing excess system oil.

Manufactured in Denmark – Delivered worldwide

All central components are produced at our facilities in Denmark using European raw materials, ensuring consistent quality and supply chain security. Our stuffing boxes are available as spare parts or complete assemblies, also from our production site in Suzhou, China – close to the world’s largest engine OEMs.

Whether you need a stuffing box for a main engine retrofit or spare parts for a running fleet, we follow the engine throughout its lifetime – ensuring availability and support long after installation.

We develop and improve products based on four principles

We strive to reduce the carbon footprint of the product throughout its life cycle

With our products, we want to contribute to actively reducing our customers’ carbon footprints

Our products should be easy to operate and maintain

Our products can be produced and delivered while reducing most possible time, material, cost and emissions