Quality and reliability

Our products

Piston rod stuffing boxes

Optimal engine operation

While a HECO piston rod stuffing box may seem insignificant, it is essential to ensuring the operation of the vessel’s engine systems. A defining characteristic of a slow-speed two-stroke engine is the sealant factor between the contaminated combustion area and the clean crank case. This highlights the crucial role of the piston rod stuffing box – our proven area of expertise.

Our products are continuously refined in close collaboration with the world’s leading engine manufacturers. It is also worth noting that our fundamental principle remains unchanged from the original solution patented by Henning Cornelius in 1962.

Three ring types

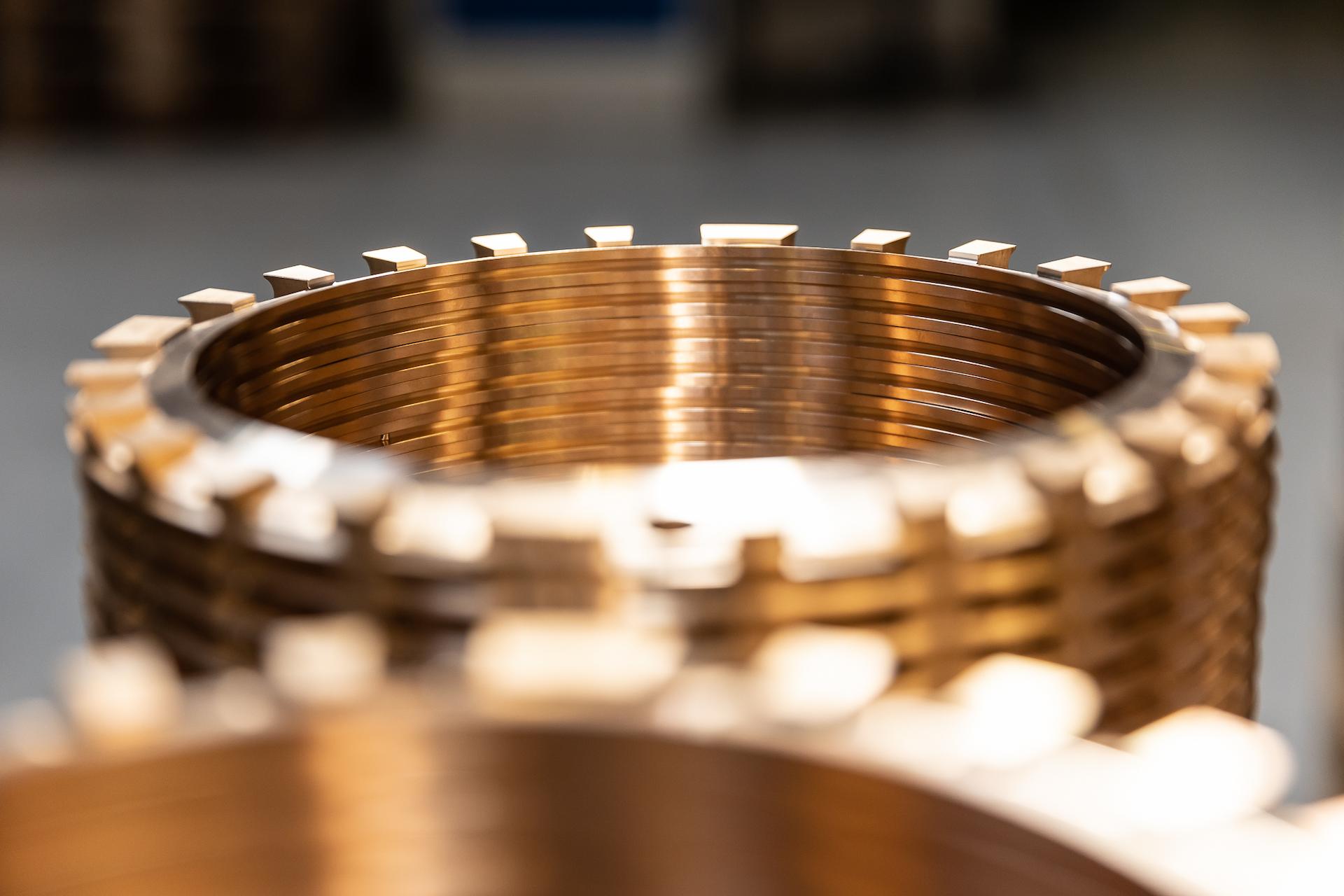

Modern piston rod stuffing boxes consist of three ring types, each of which provides a crucial function.

These are as following:

- The top scraper rings scrape impurities off the piston rod.

- Sealing rings create a pressure-tight seal between the scavenging air space and the crankcase.

- Lamella scraper rings scrape system oil off the piston rod and minimise oil waste.

We were the first company in the world to introduce lamella scraper rings with replaceable lamellas – an innovative design, demanding utmost precision in manufacturing processes to achieve the desired geometry.

Quality and precision

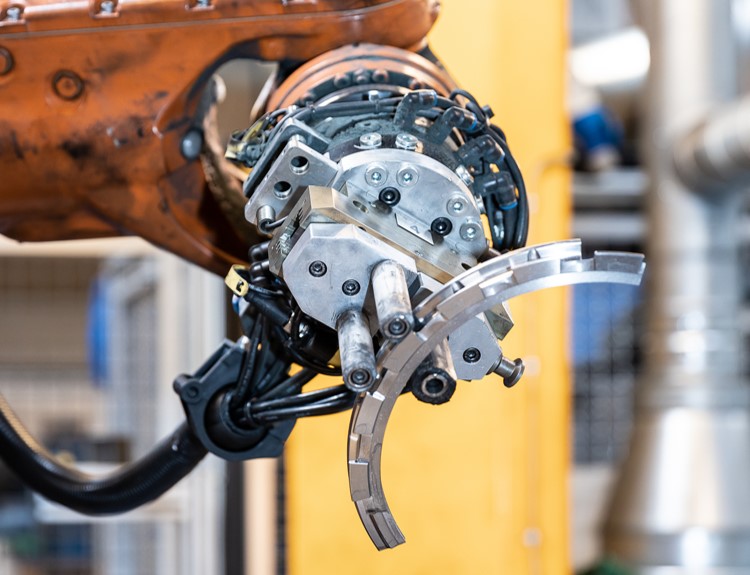

Maintaining optimal engine performance requires precision and high-quality products, which ensure that system oil waste is kept to a minimum. Over time, we have developed and advanced our manufacturing technologies, becoming experts in producing rings with exceptional accuracy, fully aligned with the designer’s drawings and specifications.

Our quality control system is certified in accordance with ISO 9001 and ISO 14001 standards. We have maintained these certifications since 1994 and remain committed to continuous improvement.

Danish reliability

At our modern facilities in Hedensted, Denmark, our skilled team works alongside advanced CNC machinery to ensure the consistent quality of our products.

All core components are manufactured in Denmark, reflecting Danish craftsmanship and utilising European raw materials. The scale of our production positions Heco International as a significant player in the market, enabling close collaboration with key suppliers of crucial materials such as bronze, ensuring a reliable and secure supply chain.

To maintain strong delivery assurance, we keep an extensive inventory of spare parts that are readily available. Our philosophy is to follow and support the engine type throughout its entire lifecycle. Accordingly, we continue to produce spare parts for all types of two-stroke diesel engines for as long as they remain in operation.

Heco International in China

In 2003, we established operations in Suzhou, China – strategically located near the global centre of two-stroke diesel engines, the majority of which are being produced in Asia.

Our facilities in China specialises exclusively in cast iron housings and forged steel flanges for piston rod stuffing boxes. From this location, we assemble and supply complete piston rod stuffing boxes to customers throughout Asia – utilising original scraper and sealing rings that have been manufactured and delivered from Denmark.

Our Chinese production sites are certified in accordance with ISO 9001 and ISO 14001 standards, consistent with the certifications held by our Danish counterpart.

Contact us

By filling out this form, your request will be shared directly with our experts. We will reply as soon as possible.