Quietly powering the world’s biggest engines

At a highly automated production site in Hedensted, Denmark, one of the most discreet but vital contributors to the global engine industry operates behind the scenes. HECO, part of G&O Maritime Group since 2015, has quietly delivered critical engine components to leading OEMs for decades.

They may not carry a logo, but HECO’s components are essential to engine performance worldwide. Leading manufacturers rely on HECO’s precision engineering to keep some of the world’s largest engines running smoothly.

“We only produce to order and exclusively for a handful of key clients. We have long-standing exclusivity agreements and are not able to market our customers’ products,” says Jesper True, Site Manager at HECO. He has been with the company for nine years and is responsible for both operations and customer relations.

In business since 1959

The original HECO ring was once so widely used that the name became synonymous with the component itself – a mark of the company’s early technical success. While the original patents expired in the 1980s, HECO remained a trusted partner by entering into exclusive agreements with engine builders and continuing to deliver at the highest level.

Today, approximately 40% of HECO’s output goes to MAN Energy Solutions, and the company continues to be part of new developments – from alternative fuels like methanol and ammonia to the shift away from lead-based materials.

“We’re not a development house, but we work closely with our customers as new engines are designed. We bring in our own testing tools and know-how to support them,” says Jesper True.

Automation, reliability, and scale

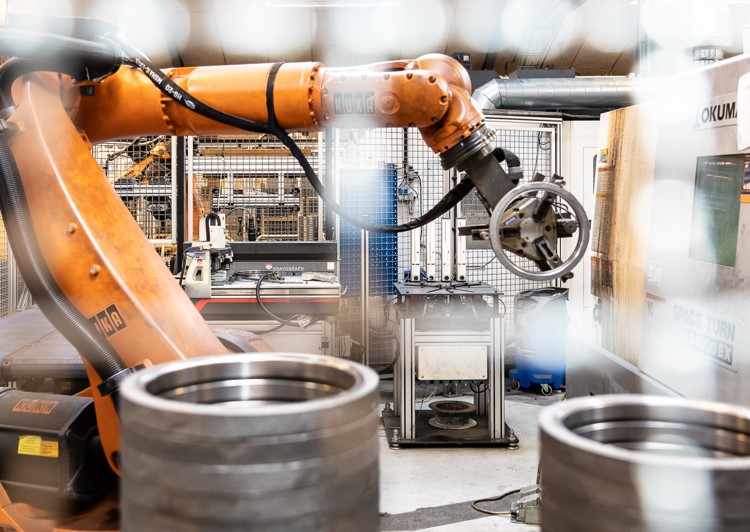

HECO operates with a high degree of automation, including 15 robots, and can maintain production costs matching Asian suppliers. HECO employs around 40 skilled industrial technicians and metalworkers. A similar number are employed at a Chinese site.

What sets HECO apart is its ability to adapt, optimise, and automate.

“We excel by streamlining processes. If we don’t stay ahead, we’ll fall behind,” says Jesper. This includes preparing for new, lead-free alloys in line with upcoming environmental regulations, as well as exploring opportunities to supply additional round components like bushings and piston rods.

Nearly 100% delivery reliability

With strong customer relationships, nearly 100% delivery reliability, and deep expertise in precision manufacturing, HECO is well-positioned to grow within its niche. As alternative fuels and environmental legislation reshape the market, the team in Hedensted is ready to support new requirements – and expand its contribution to engine builders worldwide.

“There’s potential for us to do more. If we can show what we’re capable of, I’m confident more customers will see the value of working with HECO,” says Jesper True.